National Landcare Program Bush Tucker Project

Saline Bush Foods – Developing a Paddock to Plate Supply Chain to Restore Degraded Land, Badgebup WA.

Saline bush tucker – native bush foods grown in salty conditions – has the potential to revolutionise the way we look at the 2+ million hectares of salt-affected farm land.

If we can create a reliable industry supply-chain, literally from paddock-to-plate, which farmers and traditional land owners can participate meaningfully and profitably in, there becomes a new food source for Australians plus an economic reason to invest in improving the health of salt-affected land. The benefits for the environment, cultural understanding and food security could be fantastic.

Building on a fledgling hand-picked, wild-grown bush tucker enterprise in Katanning’s Badgebup area, this project is about breaking down the constraints to upscaling, and training a wide number of other people to be able to participate in the future. We’re the guinea pigs, so that others can follow!

Media Information Pack Available here.

Lost to food production for decades due to salinity, this land will start producing gourmet food through a collaborative project between Katanning Landcare, Moojepin Foods, WAGOGA, Chatfields and the Valley Flower Farm, supported by funding through the National Landcare Programs Smart Farming Partnerships program. Sounds incredible? Watch this space!

The major areas of project activity are:

- Development of a horticultural production system, in a controlled tunnel-house environment, which can grow succulent bush tucker plants using pumped saline groundwater. This system should be able to produce out-of-season supply for the food industry, reduce harvesting labour and protect the valuable stems, leaves and flowers from damage.

- Enhance outdoor (paddock) crops of saline bush tucker, through testing techniques such as plantations, raised beds and ‘tickling-up’ of old stands.

- Developing two tractor-based machines – one for forming the bushes, the other for delicately harvesting soft stems – which will significantly decrease the labour burden and increase the reliability of supply quality from in-paddock saltbush stands.

- Training of farmers and young people in the saline bush tucker horticultural and paddock systems.

- Expansion of markets, raising awareness among consumers, effective marketing and branding of the produce and solving issues around the delivery of fresh products – such as on-site packing, product packaging, shelf-life etc – to the end consumer.

- Research into the natural resource impacts of commencing and/or intensifying production from saline land, including salinity, soil health and vegetative cover.

There was a public field day in spring 2020 to showcase work on the project.

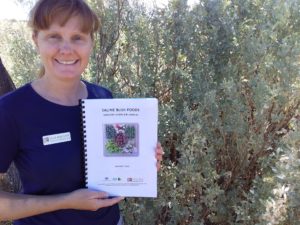

On the 27th January 2022, the “Saline Bush Foods Industry Overview Manual“ was released, capturing and sharing the learnings from the four years of project work. For a free digital copy of the manual, email ella@katanninglandcare.org.au or click here.

On the 31st March 2022 there was a comprehensive training event for landowners and managers who wish to go into saline bush tucker production on their own properties.

On the 8th of April 2022, the “Environmental Reporting for Saline Bush Foods Production” report was released. This document is the work of soil scientists Dr Jolene Otway and Dr Bede Mickan, who monitored the impact of the in-ground saline bush foods production systems on the environment. A shorter summary, used as a Training Day handout, is available here.

Project Updates

Select an update title below to read more…

Throughout the Saline Bush Foods project, two soil scientists have been carefully monitoring the environmental impact of the in-ground production systems – Wild Harvest and Plantation. The assumption was that improving productivity on these degraded soils would result in a positive health benefit also – the monitoring was to test that!

Dr Jolene Otway has been looking at soil carbon and nutrients, groundwater, habitat and salinity, and Dr Bede Mickan specialised in the soil DNA analysis. Their work has been brought together in a full report titled “Environmental Reporting for Saline Bush Foods Production”, with a shorter summary document, both available for download from the Katanning Landcare website.

In the Plantation site, the data indeed is showing a positive trajectory of improvement. Although there was significant disturbance to establish the site, soil carbon and other factors showed that recovery from the initial impact had occurred, and was continuing in an upward direction. Soil DNA showed a measured increase in species that are involved in carbon cycling (especially directly under the saltbush plants) and nitrogen fixation.

There was also a close relationship between soil nutrient content and the nutrient content of saltbush leaves, which varied across the site.

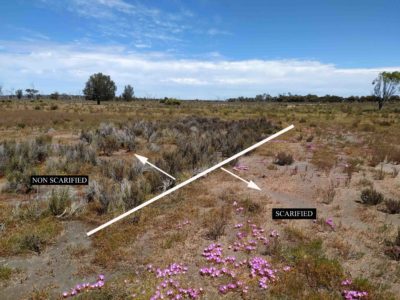

In the Wild Harvest site, monitoring showed that scarification was not a beneficial technique to support better growth and recovery. After an initial flush of growth fuelled by nutrients brought to the surface by the machine, the system collapsed and performed worse due to the now reduced amount of groundcover and plant biomass.

Un-scarified (control) areas showed high stability, and soil bacterial involved in carbon cycling were consistently present in higher numbers where plants are directly located.

No impact on groundwater levels by the increased production at the sites was able to be detected in the relatively short time-frame of the study.

Extensive data and analysis is provided in the full report.

On Thursday 31st of March, the long-anticipated Grower Training Day was held, to teach other landholders how to grow saline bush foods in any of the three growing systems.

Following the public release of the Industry Overview Manual in January 2022, six growers signed up to learn even more.

Unfortunately one participant and a number of the project team were unable to attend on the day, with many falling victim to COVID-19 isolation rules, but those that made it were in for a busy day.

Starting with an overview of sales, marketing and the future of the supply chain, the group then donned raincoats and headed to the Wild Harvest site. Here they saw the impacts of the scarification trial, had a turn at measuring groundwater in a piezometer and got their first taste of the challenges of finding the perfect specimen in a wild harvest situation.

After a delicious morning tea of karkalla sushi and fruit coulis meringues, the group then visited the plantation site. Here they saw a demonstration of the former machine in action, discussed site preparation and management before competing for the honour of “best saltbush sprig picked”. Judged by host farmer David Thompson, it was an excellent way to clarify in the participants minds exactly what the end consumer is looking for.

A stop by the production bores to look at the pump system and talk about groundwater quality was made.

A chance to sit down and enjoy a delicious lunch of pumpkin and saltbush quiche, saltbush lamb sausage rolls and a saline produce green salad was savoured over lunchtime. The break was well earned!

Afternoon saw the group head into the shadehouses to look at the irrigation set-up, get their hands dirty planting on some ice-plant seedlings, and checking out the liquid fertiliser system. The group also discussed power requirements, shadehouse design and management of pests and insects.

A convoy into town to visit the new Packing Shed was made, with KE Inc Chairman Matt Collis showing the group around, and sharing in the afternoon tea of saltbush lamb meatballs and chocolate slice.

Participants were all sent home with a copy of the restricted-release Technical Manual, as well as the Environmental Reporting outcomes.

Those that were still in Katanning that night enjoyed a meal together at the Dome restaurant, dissecting the events of the day and building relationships which will help potential new growers to become successful parts of the saline bush foods industry.

Saline Bush Foods Project Manager Ella Maesepp, wrote the following as an opinion piece for Countryman newspaper, published 14 October 2021.

I remember as a young student when salinity was known as “The White Death”, a creeping menace of immense threat to our environment, waterways, agriculture and towns. The language around it was of fear and overwhelm.

But over the last few decades, in my work with Landcare and as part of a broadacre farming family, I’ve seen that attitude change somewhat, for the better.

Through numerous public programs, research by institutions and farmer groups, and of course, good old-fashioned farmer ingenuity, we’ve developed quite a tool kit for living with the “salty scourge”. Saline pastures and saltbush for livestock feed have revolutionised the way farmers use salt flats. Deep drainage, pumping, raised beds, revegetation with salt tolerant species, crops with higher salt tolerance are all innovations that are now in use.

Salinity is still a massive issue. It still needs resourcing and research and action. It’s still taking out productive agricultural land and valuable ecosystems. But it also brings with it new opportunities.

I’ve been fortunate to spend the last four years working on a project in Katanning, funded through the National Landcare Program Smart Farming Partnerships program, epitomising the saying when life gives you lemons, make lemonade… or in this case, when life gives you salt, grow saline bush foods.

Taking a walk on the salt flats with Moojepin Foods grain and sheep farmer David Thompson will invariably have you eating plants that you ordinarily would have overlooked or stepped on. It will also change the way you think about what’s growing down on these waterlogged, sometimes smelly and generally unattractive flats.

Out of this curiosity and a chance conversation in 2017, Mr Thompson starting exploring what plants on his own salt country were edible, and with a bit of creativity, could be enticed onto the plates of the most discerning diners. And with it came a partnership, cemented through the Australian Government funding in 2018, bringing together Katanning Landcare, Moojepin, gourmet food marketer Wagoga, Chatfields Engineering, Charlotte Creek horticulturalist and social enterprise Katanning Environmental Inc to create a full paddock to plate supply chain of saline bush foods.

This project has made the next leap – as an agricultural sector, we’d already succeeded in saline plants for livestock to eat, but this was now about bringing it to direct human consumption. It’s exciting stuff.

Focussing on four species – saltbush, karakalla (aka pigface), ice-plant and samphire – the project has developed growing systems at three different levels of complexity – wild harvest from the salt flats, plantation growing in salt-affected paddocks and a Rolls-Royce shadehouse system irrigated with pumped saline groundwater. It’s done a lot of work with chefs, restaurants and the gourmet food scene to promote these “new” foods and the ways they can be enjoyed. Work on harvesting, packing, transporting and marketing have closed the gap between the paddock and the restaurant. Soil scientists have been monitoring the trial systems to see if the invigorated growth and active management of saline areas through saline foods production has a positive environmental benefit.

And the results so far have been fantastic.

Even with the rollercoaster ride that COVID-19 unleashed on the hospitality and restaurant sector, demand for the products has grown. Back in January 2019, our saltbush product sales were just under 9kg for the month, 9kg of samphire and 12kg of red karakalla. Fast forward to June 2021 and those monthly figures were 127kg of saltbush, 132kg of samphire and 98kg of red karakalla. And this is just at a very controlled small scale, while the system is still being properly developed, tweaked and refined.

When you consider that the products market for between $30 and $75 per kilo wholesale, the potential economic benefits to Australian farmers and communities is visible. It gives options for famers who have “lost” land to salinity, employment opportunities in regional communities, and “new” Australian flavours for the end consumer.

Next year, the project closes and left behind will be a fully commercial supply chain – one we hope will continue to grow. The project is developing a manual and training course to upskill others to enter the supply chain – which will be tightly managed and grown incrementally in line with growth in demand and chain capacity. It’s of no benefit to anyone to flood the market, supply inferior product or promise a volume that can’t be met. Careful and intelligent management will create opportunities for more players over the long term, giving environmental benefits to oft-neglected saline land, diversification options to farmers and rural communities, and changing the way we think about saltland agricultural production.

And it shows what can happen when people with vision can pair with skilled team members, and get support to “give it a crack”. That is, after all, the way we do things in rural Australia.

For four years a team of passionate Landcarers have been working away in eastern Katanning developing a paddock-to-plate supply chain using saline bush foods.

“Salinity is a major issue facing southern Australian agriculture,” says Katanning Landcare Officer Ella Maesepp, “and finding ways to produce viable food crops from salt-affected land, whilst improving its environmental condition can be a game changer.”

The project brought together the expertise of host farm Moojepin Foods, gourmet food marketer Wagoga, Chatfields Engineering, Charlotte Creek Horticultural, soil scientists from Terra Perma, and Katanning Landcare. After intensive work developing three growing systems – Wild Harvest, Plantation and Shadehouse, growing both consumer awareness and a nation-wide customer base, and establishing a new Packing Facility, the Saline Bush Foods project are delighted to release their Industry Overview Manual.

“The Manual is compilation of years of research, mistakes, successes and product development, all captured into one overview document.” explains Mrs Maesepp. “We hope it will help other landholders with salinity on their property to make an informed choice as to whether the saline bush foods industry may be right for them.”

Supported by the Australian Governments National Landcare Program Smart Farming Partnerships, the Saline Bush Foods project developed four product lines – samphire, saltbush, pigface (karkalla) and ice-plant – growing them on saline land or irrigated with saline groundwater. The products have been enthusiastically received by the restaurant and hospitality industry, including top restaurants such as Sydney’s “Quay” and “Fleur” in Perth, as well as venues in Adelaide, Brisbane and Melbourne.

On the 24th March 2022, landholders who are considering taking the next step into production will be able to attend a training day held at the Katanning project site, David & Sue Thompsons Badgebup property Moojepin.

“At this event, we’ll delve deep into the details of how to set-up and run these growing systems. The entire project team will be there to work closely with keen landholders, as we look toward sustainably and incrementally growing the saline foods industry,” said Mrs Maesepp.

Copies of the Saline Bush Foods Industry Overview Manual are available, free of charge, from Katanning Landcare on 9821 4327 or ella@katanninglandcare.org.au. Applications for the training course are now open, closing 17th March 2022.

Bush Foods Spring Field Day

On Thursday 15th October, in perfect spring weather, the Saline Bush foods Project threw open the gates to the public for the very first time.

Around 50 people were present at the event, which was the first opportunity to see over two years worth of work in the development of a paddock-to-plate supply chain of high value gourmet foods produced using degraded land and water.

The day began with a heartfelt Welcome to Country from Wuddi Aboriginal Tours, who are working with the project as cultural advisors, before getting stuck into the nuts and bolts of what is going on.

Project manager Ella Maesepp from Katanning Landcare described how this project, funded by the Australian Governments National Landcare Program Smart Farming Partnerships, is aiming to work out how to do every step of the full supply chain – growing, harvesting, packing, marketing and teaching.

“This project is about trying different ways, making mistakes and then eventually teaching others the successful way of doing things, so that we can grow an industry.” She explained. “We’re the guinea pigs, and in our mind is constantly ‘will another farmer be able to do this with the skills and resources he/she can reasonably access?’”

Gourmet food marketer Lance McLeod of WAGOGA introduced the group to the plants being grown in this project – ice-plants, samphire, pigface (karkalla) and saltbush – and the complexities of introducing ‘new’ foods to end consumers and restaurateurs.

“Feedback from users of the product is really important in driving how we grow the plants, and how we harvest,” explained Lance. “We need to be able to consistently supply a desirable quality product.”

Katanning Environmental Incs Matt Collis then gave the group an update on the development of a Packing Shed, at the old Saleyards site in Katanning, and how this new infrastructure will open up enterprise opportunities for the district.

The participants then split into two groups, taking the opportunity to visit two of the growing systems, before switching with each other.

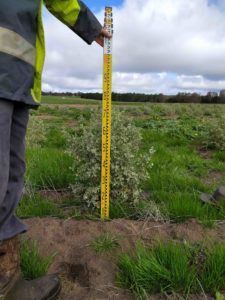

Out in the saltbush plantation site, Chatfields Dustin McCreery gave the lowdown on the saltbush variety “Seakiss” which has been selected for its human palatability requirements, before cranking up the engine on the brand new saltbush former machine.

Adapted to sit at the front of a tractor, the former trims down saltbush plants, removing much of the woody component, and is expected to be used on a saltbush plantation once every few years. Many of the farmers present thoroughly enjoyed checking out the attachment!

It paves the way for the second machine – the harvester – which is an adaption of a tea-leaf harvester as used in tea plantations in India, mounted onto a quad bike. It is able to take off the tender regrowth from the plant, in a size and condition ready for packaging.

Meanwhile, the other group were busy in the shadehouse with host farmer David Thompson and horticulturalist Tony Merceica. They viewed a number of different species – including heart leaf ice-plant and red karkalla – that are being grown on benched, irrigated only using saline groundwater from a bore sunk nearby. Powered by a stand-along solar and battery system, the shadehouse system is helping to address seasonality issues, as well as making harvesting of the product more efficient – reducing the need to bend, or to have edible sprigs covered with dirt as occurs in natural harvest sites.

A highlight of the field day was the much anticipated lunch, which showcased the bush foods being produced. Prepared like a work of art by local chef Janelle Nehme from Gypsy Kitchen Co, the grazing table featured dishes such as saltbush damper, samphire pesto, bush spiced bread sticks, cherry tomato and red karkalla relish and some decadent samphire caramel chocolate truffles!

To round out the afternoon, participants carpooled into a convoy of white utes and 4WDs to visit the wild harvest samphire sites, down on the extensive salt flats. There, the conversation about the expected environmental outcomes from increased growth, management and groundwater use that the project is hoping to achieve – and is being monitored by soil scientists – came to life.

Finally a question and answer session with the project team and Landcare Chairman Scott Newbey finished out a full, interesting and inspiring day!

Local environmental not-for-profit enterprise organisation Katanning Environmental Inc (KE Inc) have recently joined our Bush Foods Project, taking on the role of the Packing Shed business development and operation after the original delivery partner became unable to do so.

KE Inc, who already run Katanning Environmental Nursery, have just secured a block of land at the old Katanning Saleyards, which had been sitting vacant since the new Saleyards opened six years ago.

Over the coming months, KE Inc will complete site works and construct a shed on the vacant block from which to run two new operations, then fit it out with specialist equipment.

The first of these enterprises is a Food Packing Facility, commencing with providing a local service to properly process and pack bush foods produced as a result of this project – ensuring freshness and speedy delivery to the market. The site being directly across the road from the freight yard that sends the foods to Perth and beyond is an added bonus!

We expect that as the Saline Bush Foods production system is rolled out towards the end of 2021 / start of 2022, the facility will begin handling produce from potentially dozens of Great Southern farms. They will also be in place to pack for market other niche food products grown locally, which may include nuts, herbs or olives for example.

The second operation will be Katanning’s Containers for Change recycling collection depot. KE Inc recently won the contract with the WA State Government to be the local depot for people to return eligible drink containers for their 10c refund. This will also operate from the same property.

KE Inc have also applied to the Great Southern Development Commissions Regional Economic Develop grants for funds to develop the business enterprises further.

The new undertaking is expected to increase employment opportunities in Katanning, encourage farmers to produce saline bush foods for the growing supply chain, ensure fresh quality produce is received by consumers and perhaps even foster innovation in new agricultural products for the area.

Containers for Change is expected to be operational October 2020, and the Packing Facility by February 2021.

The start of 2020 has seen some great leaps forward with our horticultural setup. The shadehouses were there, but needed two critical elements to make them work – power and water!

A few weeks ago the solar power system was installed and connected up. Everything about this project is aimed at creating a system that any farmer can replicate, therefore it has to be affordable and it has to be achievable with the skill set that a farmer has. Tony Merceica, our Project team member in charge of the horticultural operations, did a great job with this brief. The solar system was designed modular, so it could be wired and tested in Perth, then simply installed onsite in an afternoon – it now sits proudly in and on a second-hand sea-container, which will double as a sheltered room (and already a table and some chairs have found their way in!). Being off-grid (battery storage), it means that a farmer could set up with own system without being limited by grid-power access, and of course, renewable power is far better for the environment! The solar power will now run the pumps for the water in the shadehouse, fans (if needed) and the all-important tea room fridge.

You can’t grow plants without water, and this Project has completely blown the minds of drillers, diviners and others – who can’t believe that it’s the salty groundwater we’re after, not the fresh! The whole point of this exercise is to grow food using SALINE groundwater – the water that doesn’t have any other use, and quite frankly, causes a lot of problems. We’re hoping that by extracting saline water out of the ground to run the shadehouse production system, we’ll also have at least a local effect on the groundwater table, lowering it and thus recovering land from salinity.

But first, to find the water! After a very disappointing drilling run on Christmas Eve 2019, in which no water was found, we were thrilled when on the 4th February 2020 (the second attempt), we struck liquid gold! Two production bores have been sunk and cased now, approximately 400m from the shadehouses. Water has been taken for testing, and sites for two groundwater monitoring bores selected. Now to trench and lay the pipes and hook up the pump!

In October 2019, Landcare Officer Ella Maesepp presented the story of our Bush Foods Project at the West Australian State Landcare Conference, held at Edith Cowan University in Joondalup.

A few things have changed with our partnership since then – Wide Open Agriculture have stepped aside as Anthony Merceica & Associates took the role as our horticultural experts, and Badgebup Aboriginal Corporation exited the project with Katanning Environmental Inc now taking the Packing Shed delivery role – but the outcomes we’re going to achieve, the excitement we feel for the Project and the positive contribution that it’s going to make haven’t changed one bit!

Check out the 20 minute presentation here

The hoops for two shadehouses have arrived by truck at the Badgebup site, and drilling of the first production water-bore commences next week!This is the start of our on-site controlled-environment growing trials – testing just how well pig-face and ice-plant can be grown in saline groundwater, in easily replicable systems, using low-cost or recycled infrastructure with a configuration allowing efficient harvesting and protection of the delicate cuts destined for the kitchen.

The hoops for two shadehouses have arrived by truck at the Badgebup site, and drilling of the first production water-bore commences next week!This is the start of our on-site controlled-environment growing trials – testing just how well pig-face and ice-plant can be grown in saline groundwater, in easily replicable systems, using low-cost or recycled infrastructure with a configuration allowing efficient harvesting and protection of the delicate cuts destined for the kitchen. Things are also gearing up for the first intake of Aboriginal Horticultural trainees in Semester 2, with Southern Regional TAFE on board to deliver the Certificate 2 level training.

Photo: Unloading the truck delivering the shadehouse hoops at the controlled environment growing site.